An angle grinder is a powerful tool you can use for cutting, grinding, or polishing various materials. It consists of several essential components that work together for efficient operation. These include the motor, disc, disc guard, handle, spindle, power Switch, and auxiliary features. Understanding these common parts ensures better performance and safety.

Common Parts of an Angle Grinder

Motor

The motor powers your angle grinder. It converts electrical energy into mechanical energy, allowing the tool to spin the disc at high speeds. Motors come in different power ratings, typically measured in watts or amps. A higher-powered motor provides more cutting or grinding strength. When choosing an angle grinder, consider the motor's power to match your specific tasks. Regular maintenance, like cleaning and checking for wear, ensures the motor runs efficiently.

Disc

The disc is the part that performs the actual cutting, grinding, or polishing. Discs come in various types, such as cutting discs, grinding wheels, and polishing pads. Each type is designed for specific materials like metal, stone, or wood. You should always select the right disc for your project to achieve the best results. Discs are replaceable, so you can swap them out depending on your needs.

Disc Guard

The disc guard is a safety feature that protects you from debris and sparks. It surrounds part of the disc, acting as a barrier between you and the spinning wheel. Always ensure the guard is securely attached and positioned correctly before using the tool. This simple component plays a crucial role in preventing accidents.

Handle

The handle provides you with control and stability while operating the angle grinder. Most models include a removable side handle that you can attach on either side of the tool. This feature is especially useful for maintaining balance during heavy-duty tasks. A firm grip on the handle reduces vibrations and improves precision.

Spindle

The spindle connects the motor to the disc. It rotates at high speeds, transferring the motor's power to the disc. The spindle also includes a locking mechanism that allows you to change discs easily. Keeping the spindle clean and free of debris ensures smooth operation.

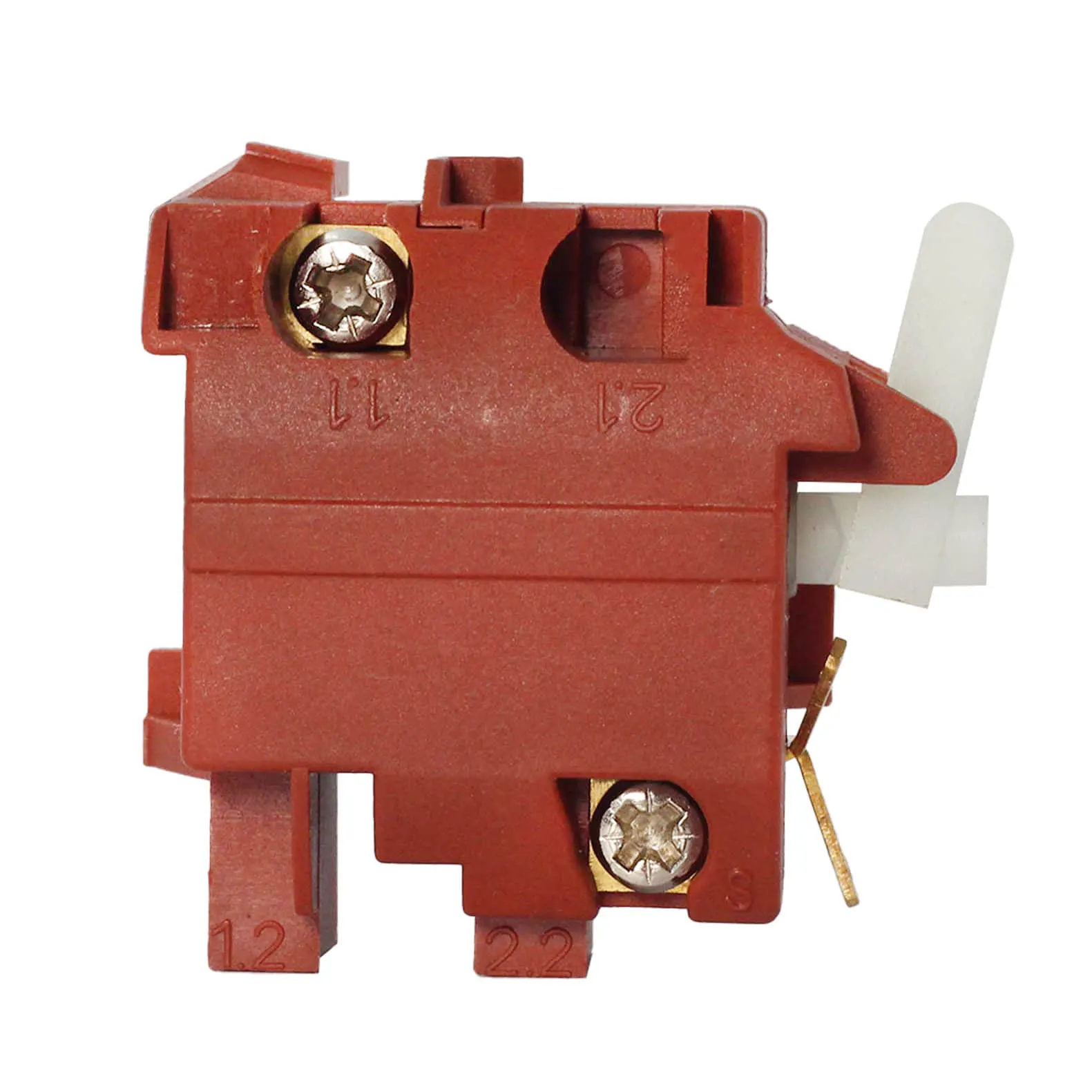

Power Switch

The power switch turns the angle grinder on and off. Some models feature a sliding switch, while others use a paddle switch. Always familiarize yourself with the power switch's location and operation before starting the tool. This knowledge helps you quickly shut off the grinder in case of an emergency.

Auxiliary Features and Their Functions

Ventilation System

The ventilation system keeps your angle grinder cool during operation. It prevents the motor from overheating by allowing air to flow through the tool. Without proper ventilation, the motor could overheat and fail. You should regularly inspect the vents for dust or debris. Blocked vents reduce airflow and can damage the motor. Cleaning the ventilation system with a soft brush or compressed air ensures the tool runs efficiently. This feature is essential for maintaining the longevity of your angle grinder.

Lock-On Button

The lock-on button allows you to keep the grinder running without holding the power switch. This feature is especially useful for extended tasks like grinding large surfaces or cutting through thick materials. By locking the switch, you can focus on guiding the tool with both hands. Always ensure the lock-on button is disengaged when you finish using the grinder. This prevents accidental starts and improves safety. Familiarizing yourself with this feature makes your work more comfortable and efficient.

Safety Considerations for Angle Grinder Parts

Role of the Disc Guard in Protection

The disc guard plays a critical role in keeping you safe while using an angle grinder. It shields you from flying debris, sparks, and fragments that may break off during operation. Always check that the disc guard is securely attached before starting the tool. Position it between you and the disc to maximize protection. Never remove the guard, even for tasks that seem simple. This small component can prevent serious injuries and ensure a safer working environment.

Importance of the Handle for Stability

The handle provides stability and control, especially during heavy-duty tasks. A firm grip on the handle reduces vibrations and helps you maintain balance. Most angle grinders come with a side handle that you can attach to either side of the tool. This feature is particularly useful for left-handed users. Always hold the handle with both hands when operating the grinder. This practice minimizes the risk of losing control and ensures precise results.

Understanding the parts of an angle grinder helps you use it effectively and safely. Each component plays a specific role in performance and protection. By familiarizing yourself with these parts, you can complete tasks with precision and confidence.